Priming and Block Sanding

Having looked at various paint removal methods in the last issue, by now we’ve stripped the old finish to bare metal—or we have an original finish where the paint is adhering with no failure problems such as cracking, chalking, or pinholes. In both cases, the process of preparing the surface for paint is similar. Your goal, through a process of gradual refinement, is to create a surface as perfectly smooth and as free from flaws as possible.

Surface Cleanliness

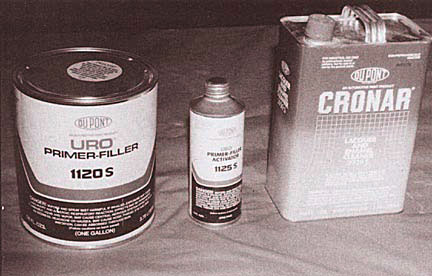

You will use a medium primer surfacer to fill and build up the flawed surface, then you’ll block-sand it to level out this primed surface. First, let’s discuss a very important requirement before priming: a clean surface. If the surface is bare metal, then a metal conditioner such as metal prep for steel and aluma prep will clean it, physically and chemically. Promoting adhesion through cleanliness and following the paint manufacturer’s instructions during each step of the process is extremely important. If that beautiful paint job you’ve spent so much effort to create doesn’t stick to the metal underneath, you’ll have to strip it off and start over.

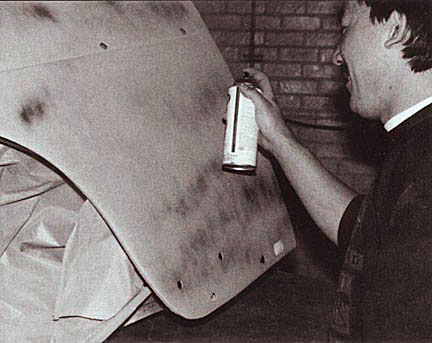

Masking

Before spraying any primer or paint, cover and protect adjacent areas from overspray. Areas to be protected should be covered with masking paper held to the body by masking tape. Good quality masking paper and tape will permit no paint to penetrate or seep through to the panel, chrome, or glass it is protecting. Tape must adhere easily to painted surfaces, chrome, glass, or stainless steel. Equally important, no adhesive must remain on the surface after the tape is removed. Years ago I had the misfortune of using some inexpensive tape. To make things worse, the tape stayed on the car for several weeks. I ended up removing it with lacquer thinner, steel wool, and a safety razor blade. The inferior tape adhesive stuck to the chrome, rubber, and glass and literally had to be scraped off. As I recall, this took me several days. Believe me, a roll of 3M tape is cheaper than several days of labor.

Primers

Even new sheetmetal panels have grinder gouges and stamping flaws that make the surface less than perfect. The typical paint job, only a few thousands of an inch thick, will only accentuate flaws. Primers and primer surfacers are designed to fill these imperfections.

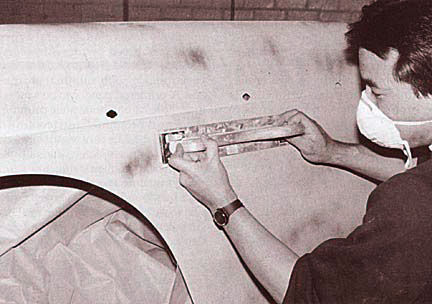

Block-Sanding

After the surfacer is dry, it is blocksanded, then more surfacer is applied. Depending upon the degree of perfection desired, this process can be repeated three to six times. Block-sanding is a process where sandpaper is used with a hard rubber sanding block. I make my own blocks out of such things as balsa wood and rubber hose to conform to the surface being sanded—flat, gradual curve, compound curve, etc. Sandpaper backed by a sanding block gradually wears down the high areas. A guide coat of contrasting color primer or paint is sprayed over the primer surfacer before sanding begins. As sanding continues, the guide coat is sanded off the high spots and left in low areas, providing a guide to sanding and identifying areas requiring additional filling. More surfacer is sprayed over these low areas, and the blocking process is repeated. Spot putty has about the same consistency as the familiar glazer’s putty but has an entirely different composition. It is usually made of the same basic material as the primer surfacer but is heavier in solids. Gouges or scratches left after the blocking process can be filled with spot putty. The typical priming and block sanding process would involve:

- Several “blockings” with 100-grit, aluminum oxide, open-coat, dry sandpaper and a long-board sanding block

- Blocking with 150-grit dry followed by a blocking with 220 wet and a hard rubber block

- Final priming and block-sanding would be done with 400 wet and a soft rubber block